Products Isosorbide

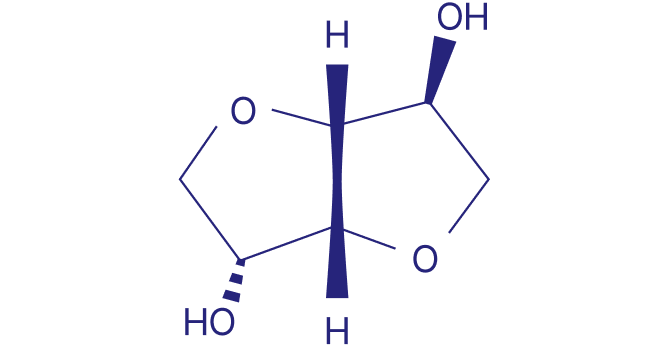

Isosorbide

Isosorbide is a biomass-based eco-friendly material, and a carbon-neutral material that can replace petrochemical materials.

Isosorbide is a fusion material made of food and chemical technology and

an Eco-friendly plastic raw material with 100% biomass content.

It is made by extracting starch from corn and then processing it into glucose and sorbitol.

Samyang Innochem produces and supplies Isosorbide first in Korea.

Applicable

Areas

Isosorbide, an eco-friendly plastic

raw material that is a high-profile material across various industries.

Plastics, made of isosorbide extracted from vegetable raw materials, is not only eco-friendly but also has excellent transparency and a hard surface compared to conventional plastic.

As UV transmittance, heat resistance and chemical resistance are improved when ISB is used for durable plastics, it is in the spotlight in various industries, such as in exterior materials for electronic products such as TVs, various mobile devices, and liquid crystal films for smartphones, dashboards for automobiles, food containers, and eco-friendly building materials.

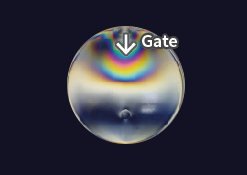

Polycarbonate, based on biomass

- Eco-friendly polycarbonate material with high bio-content and BPA free.

- Compared to conventional polycarbonate materials, improved optical properties

(low birefringence, high transmittance). - Excellent chemical, weather and scratch resistance and hardness.

- With excellent flow properties, easy to process.

Characteristic comparison :

PC based on BPA vs PC based on ISB

※ Reference : Macromol. Res., 25(11), 1135-1144(2017)

| Material Temp. |

|---|

| Fossil-based PC(TRIREX 3022IR) |

| Bio-based PC(DURABIO D7340IR) |

| 260℃ | 280℃ | 300℃ |

|---|---|---|

|

|

|

|

|

|

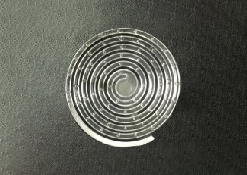

Birefringence Characteristics

| Material Temp. |

|---|

| Fossil-based PC(TRIREX 3022IR) |

| Bio-based PC(DURABIO D7340IR) |

| 260℃ | 280℃ | 300℃ |

|---|---|---|

|

|

|

|

|

|

Flow Characteristics

Product Use

-

Panel/sheet, optical film

-

Car interior materials

-

Car exterior materials

-

Mobile accessories

Polyester, based on biomass

- In the case of PEIT (Polyethylene-co-Isosorbide Terephthalate) which is based on isosorbide, it has excellent heat resistance and optical properties compared to conventional PET.

- Excellent chemical and scratch resistance.

- It can be applied for high rigidity and UV resin when used as a powder coating.

- Biodegradability can be adjusted when used as biodegradable polyester.

Product Use

-

High heat resistant food containers

-

Cosmetic containers

-

Powder coating resin

-

Polyester elastomer

-

Biodegradable polyester products

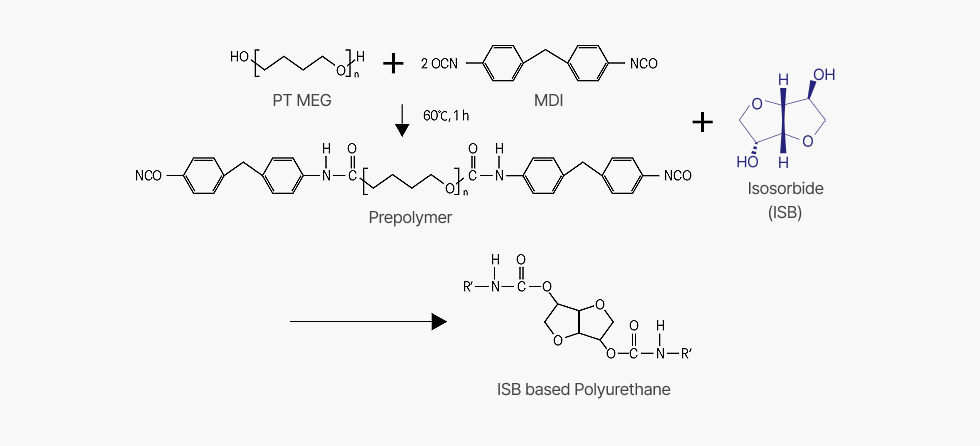

Polyurethane, based on biomass

- Can be used as biomass-based Polyol, Isocyanate and as an additive.

- Possible to develop as eco-friendly polyurethane foam, thermoplastic polyurethane, a coating agent and as an adhesive, etc.

- In the case of specialty polyurethane using isosorbide, it can be applied to various industrial purposes such as in automobiles, electrical/electronic, and as industrial materials.

Characteristic comparison : PU based on 1,4-BDO vs. PU based on ISB

-

Tensile strength

-

Thermal Behavior

-

Effect of improving yellowing

Product Use

-

Foam (Car interior materials, Insulator)

-

Coating agent

-

Glue

Isosorbide derivatives :

Bio based Acrylate, Bio polyol,

DMI, epoxy, plasticizer, etc.

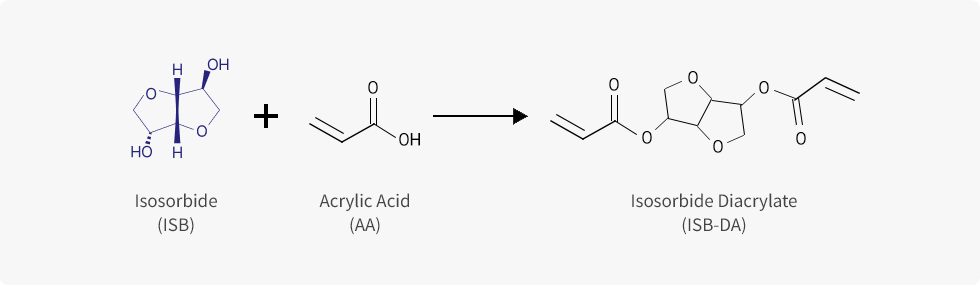

Isosorbide Diacrylate (ISB-DA)

- Manufactured through the reaction

of isosorbide and acrylic acid - Flooring material (Tile, Floorboard), Coating

applications(Woods, Decorative films),

UV ink and printing, painting materials

Key features of Isosorbide

Diacrylate (ISB-DA)

- Reduced contraction during hardening

due to excellent hardness - Low skin irritation and Biomass based

eco-friendly acrylate

Product Use

-

Coating application (Floor, Woods, etc.)

-

Inks, Printing materials and Paints

-

Adhesive promotor

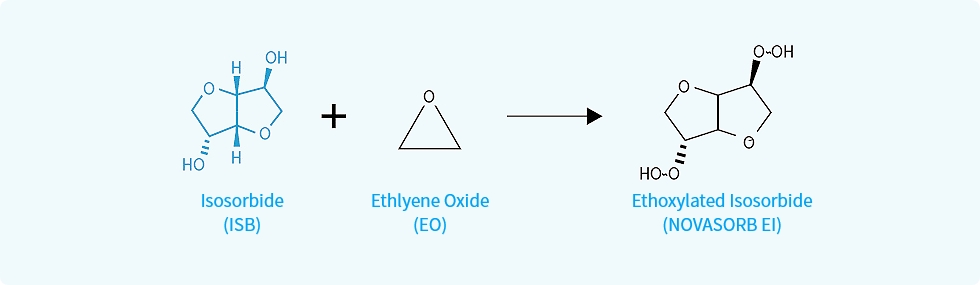

Bio polyol (NOVASORB EI/PI)

- Manufactured by adding ethylene oxide (EO) and propylene oxide (PO) to isosorbide

- Possible to be used as a monomer or additive for biodegradable polymers, polyester elastomers, and polyurethanes.

Product Use

-

Polyester elastomer

-

Polyurethane

-

Biodegradable Polymer

Others : Bio solvent (DMI), Epoxy, Plasticizer, etc.

- DMI (Dimethyl Isosorbide) can be used as a raw material and additive for cosmetic and personnel care products and has good miscibility with organic solvents, water and has excellent acid-base stability.

- In addition, it can be used as a derivative, similar to eco-friendly epoxy (BPA-free), and eco-friendly plasticizers (non-phthalate).

Product Use

-

Cosmetic & Personnel care products

-

Eco-friendly epoxy

-

Eco-friendly plasticizer